Safety management is nothing new to professional flight departments. What may be new to many departments is an organized safety structure and documented accountability that proactively manages safety risks.

Safety management is nothing new to professional flight departments. What may be new to many departments is an organized safety structure and documented accountability that proactively manages safety risks.

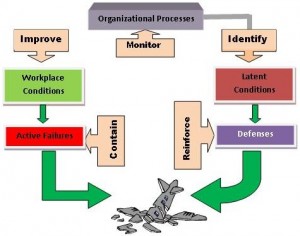

Safety system accountability expands the traditional “seat of the pant” safety management to a fully looped structured process. The system involves all personnel top down and bottom up; administration, accounting, pilots, and mechanics alike.

An aircraft is towed from the hangar-disconnecting the tow bar, wetness is noticed on the right main tire…nothing is noted or communicated; a mechanic sees hydraulic fluid on the hangar floor and cleans it up, then goes on to the next task; the crew departs; pilot makes a good landing and applies brakes…leaking hydraulic fluid heats and ignites…the right main gear was engulfed in flames…the air traffic controller calls the emergency fire rescue; the crew managed the event as trained and everybody is safe, however, curious as how could this happen?

Structured safety management should/would have required problem identification, documentation, and reporting leading toward a timely, mitigating action to the cause and remedy, i.e. 1) brought attention to the wetness when the aircraft was towed: what is the fluid-where did it come from-communicated to the DOM; 2) mechanic: where did the hydraulic fluid come from-communicated to the DOM.

GREAT emphasis was placed on the use of our incident/hazard reporting forms during our recent company training. The importance to identify, document, and communicate a potential problem on these forms was “drilled to boredom.” The information is then timely analyzed seeking ways to act on reducing the risk. No reporting=no analysis=no action=no reduced risk.

Special Services Corporation (SSC) continues to evolve toward a safety management culture that affects everybody and every task. SSC proactively seeks to identify risk through an organized and managed safety process to help predict and minimize safety risk.

Jim Alexander

Director Operations

864-242-3383

Leave A Comment